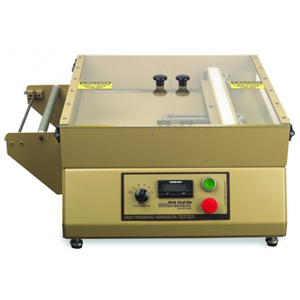

Taber Webbing Abrasion Tester

Evaluation of abrasion resistance properties of seat belts and other webbing products

For teh evaluation of materials such as safety belts, tie-downs, restraint harnesses and helmet straps.

The Taber® Webbing Abrasion Tester – Model 5820 is used to evaluate abrasion resistance properties of seat belts and other webbing products such as safety belts, tie-downs, restraint harnesses and helmet straps. Over time, adjustment hardware or common use may cause abrasion damage and jeopardize the integrity of the webbing material. The Webbing Abrasion Tester provides a cost effective means to perform abrasion testing.

Common types of materials that can be tested with this instrument include nylon, polyester, leather, polymers, and other flexible sheet materials. Included weights permit testing of webbing with breaking strengths over 13,500 N to ASTM D6770.

Description

A specimen clamp bar secures the specimen to the instrument and a specimen roller ensures an angle of 85° (±2°) is maintained between the specimen and hexagonal (hex) abrasion bar. Test specimen is weighted, and then subjected to a unidirectional reciprocal rubbing action as it travels back and forth over the hex abrasion bar. The test specimen passes over two of the six abrading edges of the 12″ hex abrasion bar during each test.

Depending on specimen width, up to three specimens can be evaluated simultaneously. Other features of the Taber Webbing Abrasion Tester include a slotted roller channel allowing a maximum stroke length adjustment of 330mm (13 inch); five preset speeds including 15, 30, 37, 45, and 60 cycles per minute; hinged, transparent safety cover; and a standard weight set of 2, 4 & 5.2 lbs. (an optional weight set of 3 & 5 lbs. is also available).

The Webbing Abrasion Tester has the capacity to test materials with a breaking strength over 13,500 N per ASTM D6770, MIL-W-23223B, US Department of Transportation FMCSA Part 571.209 and other internationally recognized test standards.

Abradants

Two (2) fresh edges of the abrasion bar should be used for each test. If only one specimen is being tested at a time, the next specimen can be abraded on a different part of the hex abrasion bar. Once the entire length of the bar has been utilized, it must be rotated to expose two (2) new edges. After the entire surface has been utilized the hex abrasion bar should be discarded and replaced.

Standard Features:

- Slotted crank arm for adjustable stroke length (0” to 13”)

- Preset speed selections (15, 30, 37, 45, 60 cycles per minute)

- Stroke length scale calibrated in English and Metric units

- Hinged, clear view safety cover

- Permits testing of up to three specimens simultaneously

- Adjustable leveling feet

- Optional weight set of 3 and 5 lbs. available

- 115V/230V operation

Webbing Abrasion Tester 5820 Includes:

- Webbing Abrasion Tester

- Hex Abrasion Rods (2 each)

- Weight Set (2, 4, 5.2 lbs.)

- Weight Attachment Buckles (3 each)

- Hex L-Key Tool

- Operating Instructions

For further information, please contact our sales team on 01223 492081 or via salespt@tendringphysicaltesting.com