The IGT Flexo Proofer Range

Removes the need for on press colour matching tests

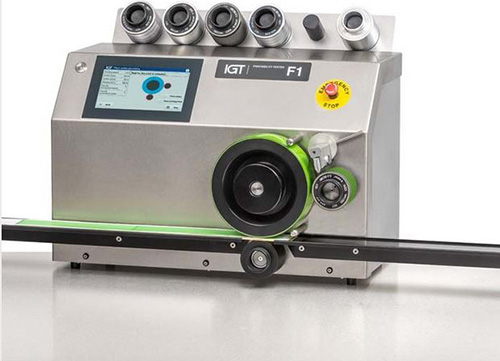

Specially designed for computerised colour measuring and colour matching systems, the IGT F1 tester series removes the need for colour matching tests on press.

Simple to operate, they are reliable and sturdily built for intensive use over a long period. Available in a number of application specific variants : F1, F1 Basic, F1-100

The F1 Range

- F1 Basic – Dedicated flexo only proofer producing a 40mm x 200mm print, has reduced choice of anilox & printing speed & pressures.

- F1 – Standard instrument producing a flexo, or gravure print of 40mm x 200mm and with full functionality.

- F1-100 – Standard instrument with full functionality for producing a flexo, or gravure print 100mm wide x 200mm long print.

IGT F1 Flexo and Gravure Proofer

Print speed, anilox and printing pressures are selectable. Two successive prints are made and the second is used, being the most consistent and produced from a pre-wetted disc. In gravure mode, the print is made directly onto the substrate and mounted onto the printing disc cylinder.

Applications:

The F1 tester colour strips can be used for a wide variety of purposes including testing print quality; use with spectrophotometers, colour measuring and matching systems; visual appraisal; density measurements including colour and density tolerances and determination of coverage; wear and scratch resistance; flexibility; adhesion; gloss; ink transfer; light fastness and resistance to chemicals.

The F1 tester is able to print on a variety of coated and uncoated materials including paper, board, plastic film, cellophane, laminate, labels and textiles. It is used regularly in the printing ink, paper and board, printing, plastics, packaging, corrugated board and labelling, resin, lacquer and coatings industries.

For flexo printing directly onto fabricated corrugated board, a special smaller diameter printing form cylinder can be supplied, offering a wider printing nip and allowing board up to 4 mm thick to be printed.

The F1 tester has a variety of printing forms, both solid, and screened in rubber and photopolymer. User printing forms can also be attached to the printing disc cylinder with foam tape.

| For use with a variety of substrates and inks | Substrate, ink, engraved roller and printing disc are simple and quick to change |

|---|---|

| Print occurs after two anilox revolutions | Printing disc can be inked up to 20 times before making the print |

| Electronic printing force and speed control | Excellent reproducibility |

| Quick and easy to clean |

| Electronic control of printing force and speed setting | Printing speed 0.2-1.5 m/s |

| Printing force 10-500 N | Maximum substrate thickness 4 mm |

| Printing width on substrate 40 mm | Printing length on substrate 200 mm (2nd print) |

| Engraved disc inked twice | Photopolymer cylinder can be inked up to 20 revolutions |

| Doctor blade angle 60°, trailing | Doctor blade pressure 6-7 N |

| A wide selection of anilox discs is available for producing a range of ink film thickness | Special engraved discs can be made to specification |

| Flexo: copper, chromium plated or ceramic, laser engraved including banded versions | Gravure: copper, chromium plated with different standard layouts including Heliotest or to user specifications Screen ruling 40-140 l/cm (100-360 l/in) |

| Volume 4-26 ml/m2 |

| ISO 2834-2 Laboratory prints with liquid inks | ISO 2836 Resistances & fastness |

|---|---|

| ISO 2846-3 Colour & transparency of gravure inks | ISO 2846-5 Colour & transparency of flexo inks |

| ISO 15995 Gloss | W-leaflets – Mottle, Colour & Density, Chemical resistance, Print through, Halftone printing |

Physical specifications:

- Weight 35 kg

- Dimensions 600 x 350 x 350 mm (W x D x H)

- Power consumption – 250 watts max.

- 115/230 V, 50/60 Hz

Operation:

The F1 tester has an inking section with an engraved anilox roller and doctor blade, a printing section with a photopolymer printing form and an impression cylinder. Ink is applied to the nip between the doctor blade and the anilox roller. During print, the ink is transferred from the anilox disc to the printing form and then to the substrate. Doctor blade, anilox disc and impression cylinder are lifted automatically.

Contact Our Sales Team

01223 492081

sales@tendringphysicaltesting.com