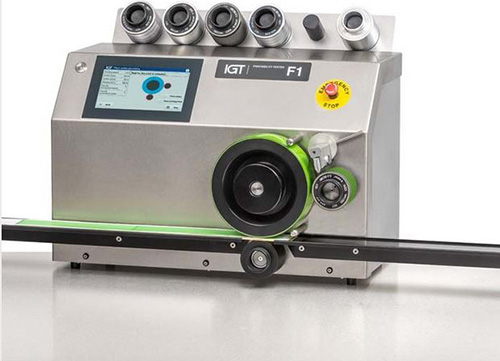

IGT F1-100 Flexo Proofer

Printability Tester For Flexo Inks And Gravure Inks

Prints 95 mm test strip. In many situations, a 40 mm print width is sufficient, but occasionally a wider print width is required. With certain special inks and/or substrates, a wider print is needed to provide a better appraisal of the printing quality. The IGT F1-100 has its most frequent application in electronics industry.

The F1-100 can be used with solvent based, UV and water based inks on a range of substrates. The F1 is available with facilities for printing on corrugated board and for gravure printing.

| Features | ||

|---|---|---|

| Print width of 100 mm | Driven anilox roller, for independent inking | Combined inking unit with doctor blade and anilox roller plus a printing unit with printing form and impression cylinder |

| Can also be used for printing in gravure mode for gravure ink | Electronic printing force and speed setting and control | Flexo or gravure mode selection |

| Printing speed: 0.2 – 1.5 m/s | Anilox force: 10 – 500 N | Printing force: 10 – 500 N |

| Impression cylinder and engraved disc are automatically brought under pressure, printed and lifted | Doctor blade is automatically placed against engraved disc and lifted | Maximum substrate thickness: 4 mm |

| Printing width on substrate: 100 mm | Printing length on substrate: 200 mm (2nd print) | Engraved disc is inked twice |

| Anilox can be inked in up to 9 revolutions | Photopolymer cylinder can be inked up to 20 revolutions |

Engraved discs

Several versions are available for different quantities of ink. Special engraved discs can be made on specification. A full range of gravure printing forms is also available.

- Screen ruling: 40 – 140 l/cm (100 – 360 l/inch)

- Volumes: 4 – 28 ml/m²

- Flexo: copper, chromium plated or ceramic, laser engraved including banded versions

- Gravure: copper, chromium plated different standard layouts or on customer specification

Doctor blade

- Doctor blade angle: 60o, trailing

- Doctor blade pressure: 6 – 7 N

Printing form and printing cylinder

The IGT F1-100 tester has several printing forms: solid and screened, in rubber and photopolymer. Customer printing forms also can be used. The printing form is attached to the printing form cylinder with foam tape.

Substrate carrier

The substrate carrier consists of a strip of plastic, covered with foam and hard polyester.

| Weight | 35 kg |

|---|---|

| Dimensions | 35 × 60 × 35 cm |

| Main application | colour measurement, colour-matching, density measurements and measurement of properties such as wear resistance, scratch resistance, fastnesses, mottle etc., Print substrate with flexo or gravure inks, Visual appraisal |

| Conformance with standards | ISO 2834-2, ISO 2836, ISO 2846-3, ISO 2846-5 |

| Forces | Anilox force: 10 – 500 N, Printing force: 10 – 500 N |

| Shaft positioning | Automatic |

| Print length and width (mm) | 2x 200 x 40 |

| Lifting system | Automatic |

| Speed range and modes | Constant: 0.2 – 1.5 m/s |

| Inking speeds | 0.2 – 1.5 m/s |

| Inks or liquids | Flexo and gravure inks |

| Printing discs | Ceramic laser engraved anilox discs, Chromium plated in copper engraved, Various line rulings and volumes |

| Sector positioning | Automatic |

| Sector type and options | Exchangeable 156 – 171 mm diameter |

| Doctoring system | Doctor blade, 60° dragging |

| Substrate requirements | Flexible substrates, Rigid substrates |

| Pre-programmed tests | If desired, these can easily be changed by the user., Standard test methods and settings are preset in the menu. |

| Inking programs | Number of doctoring revolutions 0 – 9, Number of revolutions before print 0 – 20 |

| Interfaces | USB Portal |

| Software updates | Via USB |

| Data export options | USB, CSV file |

| Power | 100 – 240 V /2.5 AT / 250 VA / 50 – 60 Hz |

| Maintenance | For average use a service check once a year is recommended |

| Cleaning | Cleaning mode for anilox and printing forme |

Contact Our Sales Team

01223 492081

sales@tendringphysicaltesting.com