IGT NBS Crumpling Device

For testing banknote paper

The NBS Crumpling Device is used in printing ink industry, printers and security printers, pigment, resin and varnish industries, research institutes and universities. Available as automated and manual instruments.

The American National Bureau of Standards (NBS) developed the NBS Crumpling Device for testing banknote paper to determine whether a particular paper, or banknote, is suitable for the rough handing that it will be subjected to when in circulation.

The test can performed with either wet or dry, printed and unprinted samples, and simulates the extreme conditions that a banknote can be subjected to. It is used by almost every printer and papermaker involved in printing banknotes, and several others sectors involved in security printing.

The Science Behind the Test

Banknotes in circulation can be exposed to considerable abuse from folding, creasing and scuffing, all of which can interfere with the adhesion of the paper fibre. This then has an impact on the attached security features and printing inks.

When paper is crumpled the interlaced fibers are disturbed, the bonds are loosened, and the disarranged structure becomes less compact, weaker and more permeable to air and liquids. The effect of the crumpling treatment is therefore measured by the change in air permeability, porosity, (water) absorption and/or in tensile strength. The properties of the paper are measured on identical paper samples before and after crumpling.

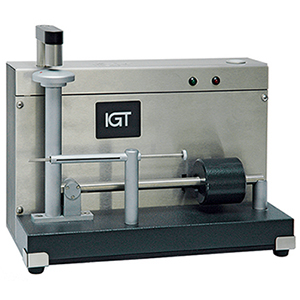

NBS Automated Pressuring Device

IGT developed this device to eliminate the variation in applied pressure in the manual test, by ensuring that the plunger is always pushed down with the same force. When the weight begins to rise it exerts a pressure of 100 N over a fixed period and so the danger of the crumpled note being pushed too far is eliminated. In this way, the tests are more reproducible and the test results more comparable.

The NBS crumpling device consists of an apparatus to roll the paper sample into a tube shape and a device in which the rolled paper tube is crumpled under a fixed pressure of 100 N.

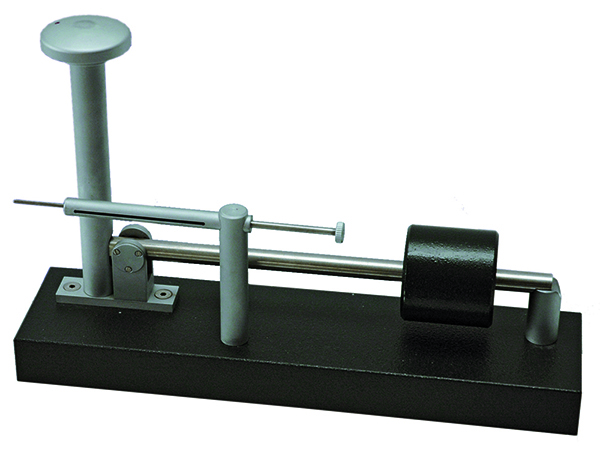

NBS Manual Pressuring Device

Applying an even pressure by hand can be more difficult, and the result can be influenced by how quickly the roll collapses. After a sudden collapse of the tube of paper there can be a sudden impact pressure and subsequent unevenness of pressure application and lack of reproducibility.

For further information, please contact our sales team on 01223 492081 or via sales@tendringphysicaltesting.com

IGT Testing Systems

Printability testing equipment and tack testing instruments for the worldwide paper industry, printing industry, graphical arts, plastics, paints, inks and coatings industry.