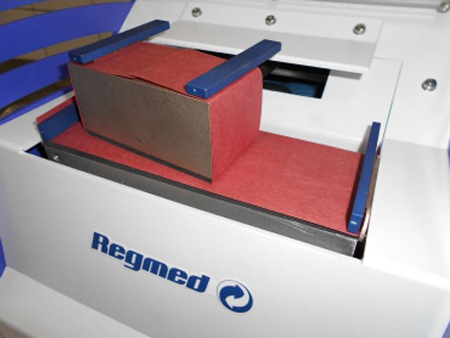

Ink Rub Tester RAS-21

Determination of resistance of printed surfaces to abrasion according to the Sutherland method

The Ink Rub Tester RAS-21 determines the rubproofness of printed samples. This can be a desirable and often critical property to understand about printed materials, which can be damaged during shipment, storage, and handling.

Suitable for use on labels, folding cartons, corrugated boxes, inserts, circulars and other printed graphics on paper, board, corrugated board, plastic and aluminum film.

The RAS-21 Ink Rub Tester offers the selection of speed, number of strokes and temperature of the heated base plate. The rotary, dual test bed has non-heatable and heatable test surfaces, on opposite sides, enabling fast and safe switching between hot and cold tests.

The magnetic clamping system is a quick and effective way of fixing the test samples to the test sled and base. The plexiglass protection screen has a safety interlock that stops the movement, if opened during the test.

The equipment is delivered with a set of tools for precision folding of the test piece + two templates.

Standards

Complies with test standards ASTM D 5264-98 AND Tappi T 830

| Technical data | |

|---|---|

| Two interchangeable test weights | Light: 908 g (2,0 lb), 100 x 50,5 mm, soft rubber coated |

| Heavy: 1816 g (4,0 lb),100 x 50,5 mm, soft rubber coated | |

| Test bed (side 1) | Standardized covered with soft rubber |

| Test bed (side 2) | Not standardized, without cover, heated up to 70 C |

| Stroke speed (programmable) | (42 to 100) cycles/min |

| Stroke | 53.5 mm arc |

| Number of strokes (programmable) | 1 to 9999 |

| Power supply | 220 VAC, 200 W, 50/60 Hz, single phase |

| Dimensions | (320 x 560 x 350) mm (W x L x H) |

| Weight | 24 kg |