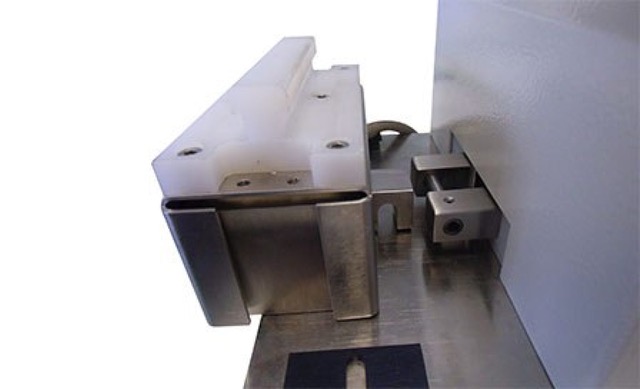

Rycolab Ink Rub Tester – Sutherland Method

Determines ink resistance to abrasion and dirt characteristics on printed surfaces

The test consists of rubbing a sample against a defined weight (2 lb or 4 lb) at different speeds. The test results are simple, visual observation.

The equipment offers four different speeds:

- 21 cycles/minute. This is half the speed of older ink rub testers and enables wet tests and tests under 5 cycles

- 42 cycles/minute and 85 cycles/minute. These are the same speeds offered by older ink rub testers

- 106 cycles/minute.

Variable speeds allow users to choose the best test process for their products. The higher speeds reduce test times. This can be essential for certain substrates, such as plastics, UV varnishes, printed films, etc.

Test procedure

Test speeds and cycles are controlled via the touch panel. The unit is set by the operator with the required number of cycles and the equipment ends the sequence automatically, after reaching that number of cycles. The touch panel displays the speed, the cycles, the weight used and the temperature conditions, when using heating weights.

Options

The equipment can be supplied with heating weights of 2lb and 4 lb, with a working temperature up to 200 ºC. This is particularly useful, when faster test processes are needed, for example with high resistance inks and varnishes.

Standards

ASTM D 5264 -98, TAPPI T830

Weight and dimensions

290 x 200 x 313 mm, 13 Kg.