Laboratory Vertical Fluter

For corrugating samples of fluting medium to be subsequently used in CMT and CCT tests

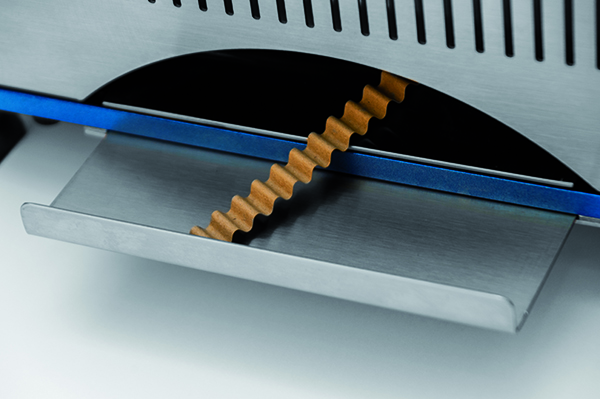

Models available for A, B and C flute. Vertical design enables easier feeding of samples. Compact, vertical design minimises bench space.

For the preparation of corrugates samples for subsequent CMT and CCT tests.

Standards

ISO 7263, DIN-EN ISO 7263, TAPPI T809, SCAN P27, PAPTAC D29

Test samples are introduced from above, and the instrument is supplied with with a set of A riffle segments. Riffle segments for Flute A, Flute B and Flute C are available, with others on request. Changing the riffle plates is very easy.

Excellent energy optimisation, with power consumption only 200 W, compared with the approximate 2,000 W required by horizontal fluters. The heating system is built directly into the rifle plate segments, making heat transmission both efficient and uniform. Takes approximately 15 minutes to reach the working temperature of 175ºC and the temperature can be set accurately to 1ºC.

“Third Hand” for correct application of adhesive tape is included (10 flutes of approx. 19mm length and 3 ± 0.1mm height).

The instrument is CE marked and optionally available with a double sample inlet for samples of 12.7 mm and 15 mm (according to GOST standard).

Test description

A sample 6 x ½” (152 x 12.7 mm) is prepared by means of a sample punch and inserted into the sample inlet at the top of the instrument. When the start button is pressed, it is molded by the heated riffle plates. The sample is ejected below and the riffle plates return to their initial position. It is important that the sample has the correct width of 12.7 mm.

| Distance between teeth: 8.5 ± 0.05 mm | Height of teeth: 4.75 ± 0.05 mm. |

| Contact pressure of the riffle segments: 100 ± 10N | Rotational speed of riffle segments: 4.5 ± 1 rpm |

| Connections | 110-220 V, 50-60 Hz |

| Net (w x d x h) | 480 x 200 x 360 |

| Gross (w x d x h) | 580 x 380 x 380 |

| Net weight | 20 Kg |

| Gross weight | 30 Kg |

Contact Our Sales Team

01223 492081

sales@tendringphysicaltesting.com