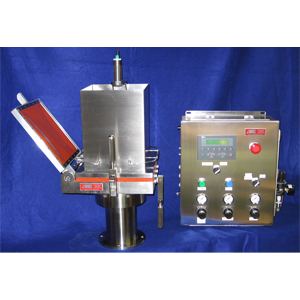

Semi-Automatic Sheet Former

Produces handsheets in pulp and paper industries

Stainless steel construction, semi-automatic operation with air agitation and pneumatic couching for easy and clean operation. Produces uniform and consistent production of laboratory hand sheets. The physical properties of the pulp can then subsequently be evaluated.

The Semi-Automatic sheet machine produces hand sheets consistently and more quickly than the manual sheet machine while reducing operator error and fatigue. Conforms to Tappi T-205 & T-219, ISO 5269/1, CPPA C.4 & C.5

Comprises – Standard sheet former, with integral pneumatic couching; drainage system, with pneumatically operated values; control box, for regulating filling, air agitation, settling and drainage.

| Standard 152mm diameter grid plate | Automatic couching eliminates the use of the 13kg roller |

| Stainless Steel Deckle Cylinder, Base, and Control Enclosure | 316 Stainless Steel Backing wire & grid plate |

| Silicone Sealing Gasket | Stainless Steel drop leg, valve and sump tank (8.5 liters) |

| Automatic control of fill, agitation, and drain | Semi-automated sheet couching |

| Couch plates, drying ring and drying plate included |

| Alternative Square sheet molds; 8″ (20cm) x 8″ (20cm) , 12″ (30cm) x 12″ (30cm) | White Water Collection and Return System |

|---|---|

| Mounted in floor standing cabinet with lockable wheels | |

| Sheet Former Dimensions: 360mm x 360mm x 610mm | Drop Leg: 890mm high |

|---|---|

| Sump Tank: 300mm Dia x 150mm H | Control Module Dimensions: 360mm x 410mm x 150mm |

| Total Weight: 56kg | Electricity – 220V / 1Ph / 50Hz |

| Air – instrument at 6 bar | |

Contact Our Sales Team

01223 492081

sales@tendringphysicaltesting.com