SpecScan

The SpecScan is now obsolete.

The direct replacement is the

Domas Multispec V Imaging System

Contact Our Sales Team

01223 492081

sales@tendringphysicaltesting.com

Original Description of SpecScan

Counts & analyses dirt, stickies, shives & contaries in paper and pulp samples

Very comprehensive, Windows based software for counting and giving a detailed analysis of dirt, stickies, shives and contaries in paper and pulp samples. Scanner based and very eay to use. Selectable test parameters to comply with Tappi and CEN Standards or can select own test parameters.

An scanner-based image analyser for quantifying dirt specks, shives and stickies. As the world’s leading software for measuring and analysing impurities in pulp, paper and paperboard:

- Enables optimisation of pulp screening and bleaching systems

- Offers greater cost control for raw materials and pulp mixing

- Enables control of the stickies content in recycled fibre

- Provides accurate, reproducible results for the day-to-day quality control of reel-to-reel dirt content

SpecScan offers versatile image analysis by combining a desktop scanner with advanced image analysis technology. The generated reports provide images that can be stored for closer inspection on screen or sent to a printer for inspection and archiving.

SpecScan provides extensive sample data including definable-area histograms, grey-scale statistics, speck coordinates and sizes, sheet summaries and category listings.

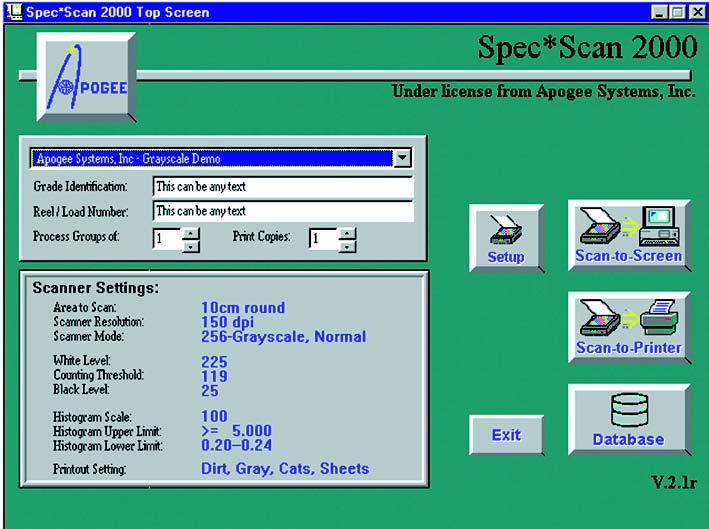

SpecScan software includes two operating modes.

SpecScan 2000 analytical

A full grey-scale specimen sheet image is presented for manipulation and analysis using the grey-scale analysis tools and is used to set the measurement parameters for the production mode. All set-up parameters are displayed on a single screen. There is also a reverse threshold for measuring objects lighter than the background, database management and image zooms to x 64.

SpecScan 2001 mill operations

Using the parameters set in the analytical mode, this mode quickly displays and prints out the critical measurements as numbers and does not permit measurement parameter changes. The automatic database manager can record all measurements for subsequent review.

In both operating modes, test data can be automatically transferred to a local area network server.

Standards

TAPPI T-213, T-437

| Analyses, measures, counts and sorts specks, dirt, residual ink, pulp shives, printed patterns and other objects that optically contrast with the paper substrate by their size and reflectivity | Accepted standard in laboratory testing and for quality control of paper with more than 250 units sold worldwide |

| Ten speck classifications can be determined following size and/or grey scale and/or eccentricity | Total grey image (false colour projection) with higher resolution can be printed immediately |

| Two frequency histograms can be displayed: Division within speck surface; Division over total measuring surface | User-friendly set-up options that support over 100 scanner configurations, threshold settings, print output and operational modes |

| Threshold setting can be set manually, or automatically, depending on the requested test procedure | Inverse threshold available for sticky analysis on black filter paper |

| Transmission light can be used for dirt analysis on black filter paper | Sample dimensions: following TAPPI standards or freely determinable in cm or inches (circle or rectangle) |

| Specks can be enlarged up to x64 | Calculation of average, maximum and minimum grey-scale value |

| Calculation of diameter, eccentricity and coordinates of dirt speck location | Operates with Microsoft Windows 10 |

| Compatible with Umax Powerlook III, Powerlook 2100, HP7400, Epson 6400 scanners | Compatible with 64 bit Operating System |

For further information, please contact our sales team on 01223 492081 or via sales@tendringphysicaltesting.com