Taber Scuffing Head Attachment

Bracket attached to the Taber Rotary Platform Abraser to hold the scuffing head at a 100° angle to the specimen holder

Mounted on the left hand abraser arm mount, a scuffing head and weight are used in place of the abrading wheels. As the table rotates, the scuffing head is dragged across the specimen surface.

A bracket is attached to the Taber Rotary Platform Abraser and mounted to the inside riser mount of the left abraser arm. The scuffing head is held at a 100° angle to the specimen holder.

The vertical centre line of the scuff head is positioned 32 mm from the specimen holder centre pin, and is centred under a weight (0.45kg or 0.9kg) in a horizontal alignment with the centre pin. The Taber Abraser is operated in the normal fashion, but with the abraser arms stored in the upright position and the vacuum system not utilized. As the specimen holder rotates, the scuffing head is dragged over the specimen surface.

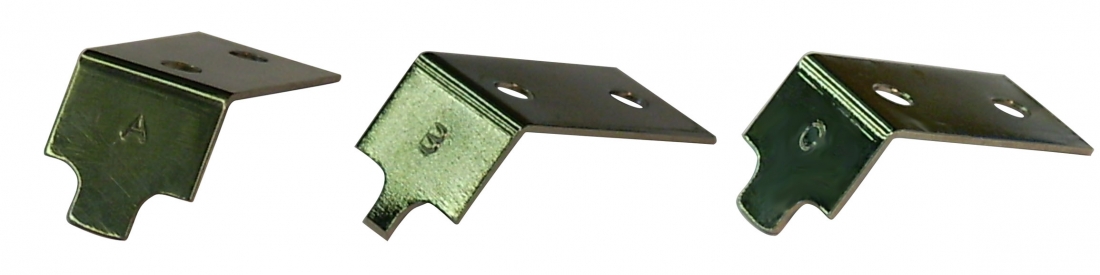

With a hinged design, the scuffing tool may be raised when not in use. Three unique profile scuffing head configurations are available.

- Scuffing head type “A” is similar to the flat blade of a screwdriver. The blade is approximately 8 mm wide.

- Scuffing head type “B” has a knife-edge and the blade is approximately 4 mm wide.

- Scuffing head type “C” has a radius edge and the blade is approximately 8 mm wide.

Scuffing Attachment Model 503-13 – satisfies Ford Test Method BN 108-04 and SAE J365 and includes “A” and “B” scuffing heads along with a 0.9kg weight.

Scuffing Attachment Model 503-1 – satisfies General Motors Test Method GM9911P and includes “C” scuffing head and a 0.45kg weight.

For further information, please contact our sales team on 01223 492081 or via salespt@tendringphysicaltesting.com