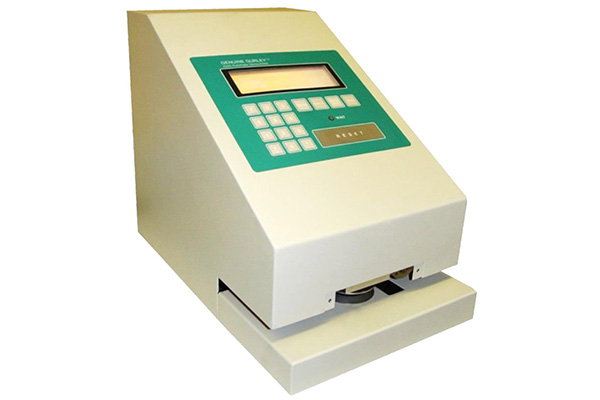

Gurley 4340 Smoothness Tester and Densometer

Measures smoothness and porosity / air permeance

Gurley microprocessor controlled densometer to provide a result in seconds, regardless of the sheet porosity. Measures smoothness and porosity. Sample strip drive included.

This unit measures the air permeability and smoothness of many different types of sheet materials. The Gurley Smoothness Tester & Densometer combines the capabilities of textile, standard and high-pressure densometers, S-P-S testers as well as programmable digital timers.

Standards: ISO 5636/5, BS 5926, CPPA D-14, SCAN P19, P53, APPITA/AS 1301-420, TAPPI T-460, T-490, T-536-88, ASTM D726-5, D202-77

Applications:

- Manufacturing and printing – to control the selection of materials affording the appropriate degree of liquid (ink, varnish, sizing) absorption

- Testing filters, porous bags and materials where controlled porosity is essential

- Testing insulating materials for air resistance

- As a supplement to other physical tests, enabling regulation of manufacturing process to give the desired formation, appearance or strength, there being a close correlation between air permeability and the other properties of a material

Overview:

Model 4340N differs from the traditional manual densometers in several ways:

It uses up-to-date mass flow and servo-regulator technology to provide a quick, accurate, oil-free test. Pneumatic cylinders guarantee a consistent clamping pressure and the automatic test feature allows a sample to be tested several times without constantly opening and closing the test area by hand. The addition of an auto-drive mechanism enables the number of tests as well as the span that they are tested over to be programmed.

Having several state-of-the-art mass flowmeters and a servo-regulator, the Gurley 4340 can accurately test both low and high flow materials that have traditionally tested between 0 – 50,000 ‘Gurley Seconds’. On ‘AUTO-SELECT’ the 4340 automatically chooses the optimum test pressure, based on the amount of flow recorded on the corresponding flowmeter and then displaying the test time. At the end of each manual test, results can be toggled between Gurley units, Bendsten, Sheffield or Bekk equivalent units.

| Air permeability and smoothness testing with one instrument | Automatic and manual testing |

|---|---|

| Automatic sample transport | RS-232 interface and printer connection |

| Rapid results |

| Air permeability | Smoothness |

|---|---|

| standard Gurley (corresponding Model 4110, 4190) | standard Gurley |

| low-pressure Gurley (corresponding Model 4118) | calculated Sheffield units |

| high-pressure Gurley (corresponding Model 4150, 4250) | calculated Bekk units |

| calculated Sheffield units | calculated Bendtsen units |

| calculated Bendtsen units |

Options:

Compressor and air filter/regulator/dryer combination

Dot matrix printer, roll fed

Interchangeable orifices (1.0 standard, 0.25 and 0.10 sq in optional)

Requirements:

Instrument air – minimum 4.5 bar

Power – switchable 110/220 V

Physical specifications:

23.5 x 40 x 32 cm (W x L x H); Net weight – 13 kg