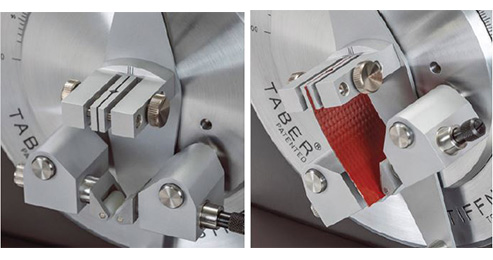

Taber V-5 Stiffness Tester

Accurate and responsive method for measuring small load increments to evaluate the resistance to bending

The Taber V-5 Stiffness Tester determines the bending moment, required to deflect the free end of a vertically clamped specimen 15° to the left and to the right, when a load is applied at a constant bending length.

Readings are taken in two directions and averaged, to determine the stiffness of the test piece. The resistance to bending is calculated from the bending moment.

Ideal for materials such as paper, paperboard, plastics, metals, non-wovens, textiles, rubber, felt and many others. Wire and cable stiffness characteristics can also be evaluated.

Standards:

- Tappi T489 or ISO 2493 for most paper or paperboard

- Tappi T566 for papers of low grammage or with high flexibility and which exhibit bending stiffness in the range of 0 to 10 Taber Stiffness Units.

There are nine distinct testing ranges, which means that materials that are extremely lightweight and flexible as well as materials that are very rigid can be tested. Each range has a specific roller position and pendulum load. These are adjusted through supplementary weights.

| Standard Features | |

|---|---|

| LCD operator touch screen interface with selectable display options | Graphic display of test range set-up |

| Test specimens up to 7.5 mm thick | Nine (9) distinct ranges |

| Predetermined specimen length, deflection angle and rate of loading ensure reproducible test results | Output in Taber Stiffness Units (gram-force centimetre) or millinewton meter |

| Easily store data and transfer via USB drive | Factory calibrated to accuracy of ± 1% of full scale |

| Compensator Range Weight | Taber Unit Range Weights 500, 1000, 2000 |

| Calibration Specimen |

Optional Accessories

- Triple cut specimen shear

- Sensitivity range attachment

- Calibration specimen

- Auxiliary range weight set (3000 & 5000 units)

Contact Our Sales Team

01223 492081

sales@tendringphysicaltesting.com