ProGage Touch

Touchscreen, precision deadweight thickness guage

Manufactured by Thwing Albert, this colour touchscreen micrometer uses state of the art measuring technology for high accuracy. Full statistics and profiling capability come as standard and the unit is available in a range of specifications to meet international test standards.

The ProGage Touch supersedes the industry leading Progage. It’s advanced technology quickly and accurately measures the thickness of sheeted material, such as paper, films, tissue and towelling, non-wovens and textiles.

The anvil design ensures excellent parallelism, zero stability and calibration. The instrument has a variable speed motor and a pressure foot that can perform up to 20 test cycles per minute, while maintaining a high degree of accuracy.

The wide range of selectable and customisable testing parameters include the measuring speed distance, the dwell time, opening distance and the pressure foot speed. In conjunction with a selection of pressure feet diameters and weights, this enables the unit to be configured to most test standards.

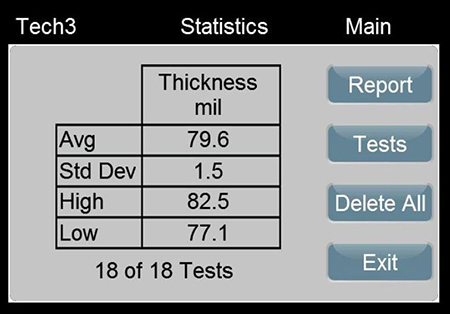

The ProGage Touch Micrometer is capable of continuous, or single testing and statistical analysis, including average, high, low and standard deviation. Performed automatically, the results are displayed instantly or can be printed at the touch of a button.

User profiles are password protected to limited access to specific screens and lock the ability to modify testing parameters.

Compatible with MAP4 software, a Windows® based software package that gives enhanced data analysis and reporting capabilities. Also compatible with Data Acquisition Software (DAS), another Windows® based software package that enables data to be collected and additional statistical analysis.

| Standard Pressure Feet | ||

|---|---|---|

| Paper Foot | 0.630” (16mm) Dia, 50.33 kPa | Complies with ISO 534 + Tappi T411 |

| Film Foot | 0.250” (6.35 mm) Dia, 51.71 kPa | Complies with ASTM D6988 + D374 (A, B, C, D) |

| Film Foot | 0.250” (5.35 mm) Dia, 172.4 kPa | Complies with ASTM D6988 + D374 (A, B, C, D) |

| Tissue Foot | 1.406” (35.7 mm) Dia, 2.0 kPa | Complies with ISO 12625-3 + Tappi T580 |

| Non-woven Foot | 2.221” (56.4mm) Dia, 0.5 kPa | Complies with EDANA 30.4-89 + ISO9073-2 |

Other feet can be made to meet a wide variety of sizes and weights.

| Measuring Range Options | ||||

|---|---|---|---|---|

| Measuring range | 1000 µm (40 mil) | 2500 µm (100 mil) | 5000 µm (200 mil) | 12700 µm (500 mil) |

| Dwell time | 2 s | 2 s | 2 s | 2 s |

| Accuracy and parallelism | ± 0.001mm | ± 0.0012mm | ± 0.0054mm | ± 0.013mm |

| Display resolution | 0.001mm-0.1 µm | 0.001mm-0.1 µm | 0.005mm-0.5 µm | 0.01mm-1 µm |

Options

- Magnetic augmenting weights – to enable measurements to be made under different foot pressures without changing the measurement foot

- Sample feeder – an automatic strip feeder is available for cross-reel profiling and roll or strip feeding up to 177mm wide. Settings range from 0.1 inch (2.5 mm) to 20.0 inch (508 mm). Speed 84mm / sec.

- Foot switch – the foot actuated control enables test to be started with one press of the foot, leaving hands free for inserting test samples

- Compact 40 column printer – formatted reports can be printed on demand, showing test results, a statistical analysis for a group of tests.

Key Features

| Touchscreen interface | Interchangeable pressure feet and augmenting weights | Variable speed motor – up to 20 tests/min | Rigid frame for zero & parallelism stability |

| Store up to 99 samples | Results: Average, High, Low, Standard Deviation | Single or continuous test mode | Easy unit conversion: mil, μm, mm, inch |

| Adjustable opening distance between the pressure foot and anvil | Send data direct to USB flash drive | PC connectivity via USB port | PC compatible, RS-232 port |

| Weight | Nett – 24.7kgs, Gross – 28.3kgs |

| Dimensions | 255mm (W) x 319mm (D) x 404mm (H) |

| Industry | Corrugated, Foils/Metals, Medical, Nonwovens, Packaging, Paper, Paperboard, Plastic Film, Pulp, Rigid Plastics, Rubber/Foam, Tissue, Textiles |

| List of Standards | ASTM D374, ASTM D645, ASTM D1777, ASTM D6988, BS3983, BS4817, BS3983, BS4817, DIN 53105, DIN 53353, EDANA 30.4-89, EN20534, ISO 534 Preferred Method, ISO 3034, ISO 4593, ISO 12625-3, TAPPI T411 |

| Accuracy | 40 mil: ±0.00004 in (±0.001 mm), 100 mil: ±0.00005 in (±0.0012 mm), 200 mil: ±0.00025 in (±0.0064 mm), 500 mil: ±0.0005 in (±0.013 mm) |

| Parallelism | 40 mil: ±0.00004 in (±0.001 mm), 100 mil: ±0.00005 in (±0.0012 mm), 200 mil: ±0.00025 in (±0.0064 mm), 500 mil: ±0.0005 in (±0.013 mm) |

| Display Resolution | [40 mil: 0.00001 in, 0.01 mil, 0.001 mm, 0.1 micron] [100 mil: 0.00001 in, 0.01 mil, 0.001 mm, 0.1 micron] [200 mil: 0.00005 in, 0.05 mil, 0.005 mm, 0.5 micron] [500 mil: 0.0001 in, 0.1 mil, 0.01 mm, 1 micron ] |

| Opening Distance | 65 to 750 mils (1.65 to 19.05 mm) |

| Throat Depth | 120.6mm |

| Measurement Speed Distance | Range from 0.0005 to 0.500 in (0.012 to 12.7 mm) |

| Dwell Time | 0 – 20 seconds (selectable) |

| Pressure Foot Speed | 0.025 to 0.500 in/sec (0.64 to 12.7 mm/sec) |

| Pressure Foot Diameter Size | 0.19 in to 2.221 in (4.83 mm to 56.41 mm) (Special sizes available), (Special applications allow interchangeable pressure feet option) |

| Pressure Foot Anvil Size | Standard: 2.5 in (63.5 mm), Optional: 4.25 in (107.9 mm) – meets EDANA method |

| Sample Rate | 128 samples per second, during a test |

| Power Consumption | 120-230VAC, 36VA |

| Power Requirements | Input Voltage: 120-230 VAC ±10%, Frequency: 50-60 Hz |

| Software Available | DAS / MAP4 |