Cleaning Solvents for IGT Printing Discs and Top Rollers

Recommendations direct from IGT

Please Note!

- Never soak the top rollers or printing discs in any cleaning agent

- Never use any of the UV cleaning agents for conventional rollers

- Never leave any rubber part of the rollers resting on another surface while not in use

- Always store the printing discs on their core in a cool and dark place, free from heat and chemicals

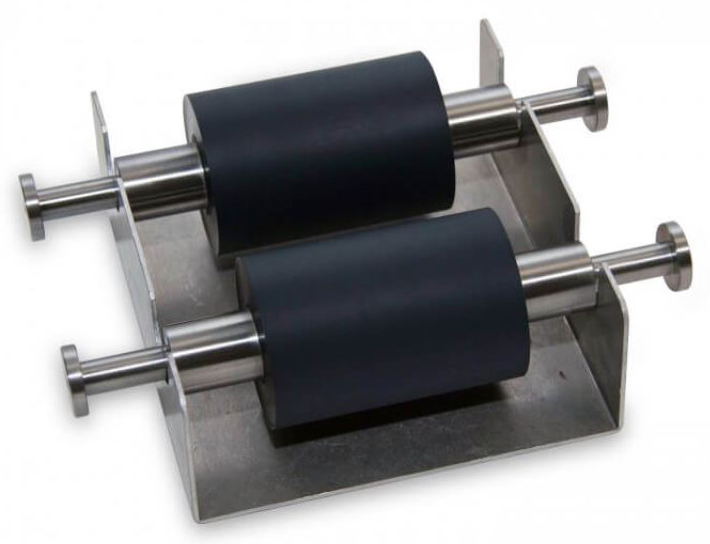

- Always store the top rollers on their core or resting only on the steel core, preferable on the special carriers.

Conventional inks

| CLEAN WITH | DO NOT USE |

|---|---|

| White Spirit | Ester like Ethyl Acetate |

| Cleaning Naphtha | Ketone like Acetone |

| Lighter fluid | Aldehyde |

| Turpentine | Methyl Ethyl Ketone (MEK) |

| Boiling point (100 – 140 °C) with less than 2% aromatic contents |

.

Black rubber discs with art.nr. 402.6xx

| CLEAN WITH | DO NOT CLEAN WITH |

|---|---|

| White Spirit | Ester like Ethyl Acetate |

| Lighter fluid | Ketone like Acetone |

| Cleaning Naphtha | Aldehyde |

| Turpentine | Methyl Ethyl Ketone (MEK) |

| Boiling point (100 – 140 °C) with less than 2% aromatic contents | |

| Alcohol like ethanol |

.

Other black rubber UV discs and UV rubber blanket discs

| CLEAN WITH | DO NOT USE |

|---|---|

| Ethyl Acetate | White Spirit |

| Acetone | Cleaning Naphta |

| Methyl Ethyl Ketone (MEK) | Lighter fluid |

| Ethanol | Turpentine |

| Spiritus |

General

The higher the boiling point, the longer it takes before the cleaning solvent has been evaporated, the longer it takes before you can make the next print with the printing disc.

IMPORTANT:

If in doubt about a cleaning agent, please contact Tendring Physical Testing on 01223 492081 or via sales@tendringphysicaltesting.com

If possible and appropriate, please send a recent SDS of the specific cleaning agent, so that we can investigate its suitability.